Fabrication Lab

The FAB LAB at Avantika is a state-of-the-art lab consisting of highend digital fabrication and manufacturing machinery consisting of an array of flexible computer-controlled tools, that cover several different length scales and various materials, with the aim to make "almost anything" and cater a platform for new ideas and innovation. Laser Cutting/Engraver 3x2 for Non-ferrous materials, NC Mini Mill Machine Bench Top Model (MDX 540 A 3D, 4 AXIS), CNC Router Machine for soft metal, plastic, wood, Thermocol Cutting Machine (Hot Knife),3D Printers, Vinyl Cutter/Plotter Machine

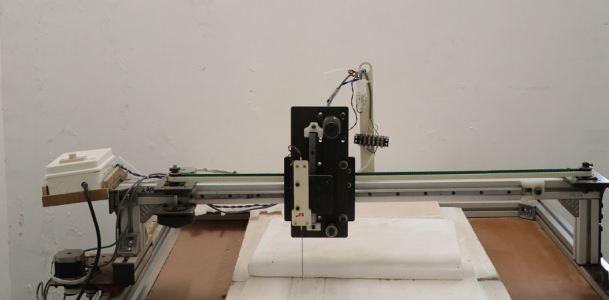

CNC Router

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut joinery such as mortises and tenons.

Laser Cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material.

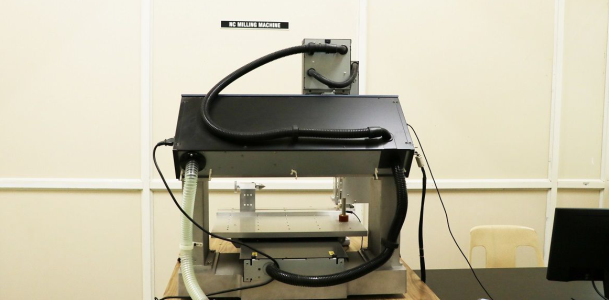

NC Mill

Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations.

Thermocol Cutting

A Thermocol Cutting Machine in a university fabrication lab helps students create models and prototypes using heated nichrome wire that melts and cuts thermocol with precision. It operates manually or through CNC control, following digital designs for accurate shapes. The process teaches students thermal cutting principles, CNC operations, and model-making skills. Proper ventilation and safety measures are essential as melting thermocol releases fumes

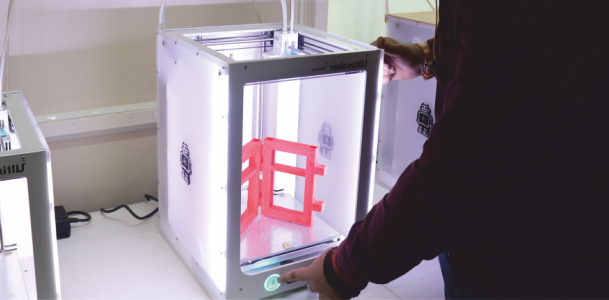

3D Printing

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together (such as plastics, liquids or powder grains being fused), typically layer by layer.

Vacuum forming

Vacuum forming is a simplified version of thermoforming, where a sheet of plastic (in various forms HIPS (High impact polystyrene) for low impact products, or for Bathroom shower trays ABS, and exterior vehicle parts HDPE, plus various other types of vacuum formable materials) is heated to a forming temperature, stretched onto a single-surface mould, and forced against the mould by a vacuum.